6 Benefits to Investing In 3d Printing

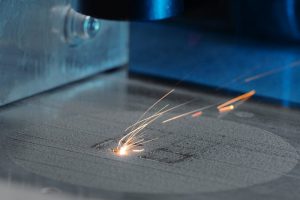

The invention of 3D printing is believed to be the most revolutionary technology in the manufacturing sector today. It eliminates constraints and reduces the time it takes to manufacture products. 3D technologies reduce errors and maintain confidentiality in the manufacturing process. It is efficient compared to the traditional manufacturing process. This article discusses six benefits of investing in 3D printing.

#1. It is faster

Conventional manufacturing takes a lot of time. It entails preparing the substrates and injection of molds before producing the final product. But 3D production starts from prototype and ends with the creation of the final product. It is faster and gives the manufacturer time to check the prototype. So, it takes a few hours before the final product is ready. But the conventional manufacturing method takes several weeks before the product is ready.

#2. Reduces cost

Costs affect business profitability. So, one of the goals of any business is to adopt strategies that bring down the costs. 3D printing is one of the strategies. It uses less material, less machinery, and less labor. It creates parts of any product in just a few steps. It increases efficiency levels and saves time. Furthermore, 3 D printing requires fewer people compared to traditional manufacturing. Each 3D printer requires just one operator. Once it is started, it begins the automated processes. This is critical in reducing the number of people that must be hired.

#3. Reduces wastes

Most of the conventional manufacturing methods result in a lot of wastages. This is not the case with 3D printing. 3D printing uses the exact amount of material required to create a product. So, there is very little wastage. Also, when you use technology, you will not waste time recycling wastes.

#4. Improved Quality

Cases of poor design are rampant in traditional manufacturing. It results in low-quality prototypes. While using injection molds, you cannot be assured of the quality. Sometimes you get quality products, and in other cases, you end up with low-quality products. But this is not the case when you choose to use 3D printing. It allows you to assemble your product through automated step-by-step procedures. This results in superior designs. Also, it leads to the production of quality products.

#5. Eliminates costs associated with storage

In traditional manufacturing, it takes weeks before products can be produced. Also, the production process may need to go through several stages. It means that the finished goods must be stored in the factory before the required number of products is reached. It requires plenty of space to store finished products. Also, there could be other associated costs that make the whole process expensive. But when you chose to use the 3D technology you eliminate all this. The process is efficient and produces the required number of goods in a shorter time. So, you only produce enough goods to be sold. Thus, you don’t need to overproduce anything and it reduces the need for storage spaces.

#6. Confidentiality

When using 3D printing, no other party can claim that they own the innovation. When you manufacture products using the technology, it ensures that the design will never leave the factory premises. This is critical in safeguarding intellectual property. You will keep all innovative design in-house, and so it guarantees confidentiality.

There are many other benefits associated with 3D printing. It is faster and efficient. Also, it reduces the cost of production by a great deal. This makes it preferred compared to the traditional method. Read our complete guide to 3d printing to learn more.